TALK TO US ABOUT WHOLESALE BUYING

IT’S WHAT WE’RE KNOWN FOR...

The New Standard in Quality + Innovation

Curiosity is the root of all knowledge and success here at Flashed! We analyze problems with a scientific approach, reasoning what causes them. The iterative process to solve these issues may take time but it’s worth it in order to create innovative products that adapt to any terrain indoors or out!

EVOLUTION

For the last two and a half decades, we’ve been there as bouldering pads morphed from duct-taped sofa cushions into refined landing systems. River rock, chipped rubber, and even moveable pads were commonplace not that long ago in climbing gyms; now gym padding is clean uniform attractive easy to maintain with a dialed-in impact attenuation response capable of handling hundreds or thousands of climbers daily. Adapting and evolving to these changing demands has always been essential for us here at Flashed where we have led the industry by setting the standard.

It’s been a wild ride so far and we look forward to taking things forward from here. Here is a short timeline description of our story:

Continuous Development

Nothing stays the same, everything is always on the move, shifting, evolving. Over our 27yr history, Flashed has always strived to be at the forefront, or even ahead, of that leading edge.

Demands on products, methods of application, a growing climbing community: these are always changing and our commitment is to keep on top so you can trust any product that has our name on it. Both today and into the future.

Materials Research

For any product, it simply has to work, and work well. Along with intelligent design and proper field testing the dependability of a product is based on the materials used. For this reason we spend an inordinate amount of time researching materials to get this right. This approach permeates all of our products and we trust you’ll recognize the difference.

Padding

The majority of climbing padding consists of polyethylene (PE) and polyurethane (PU) foams. PE foam is the harder closed-cell product used as a force dispersion layer (like gymnastic carpet bond) while PU foam is the open cell soft and squishy material used in bouldering pads and under route flooring. Although data is available from other industries, climbing is a dynamic impact sport and specialized equipment is necessary.

Chalk Research

Our story was born with the chalk ball in 1995, but we didn’t stop there. Over the last two decades, we’ve innovated, tested, and strove to create the best-performing chalk on the market. Recently, we teamed up with UBC to devote substantial research to climbing chalk.

Our inquisitiveness is grounded in a genuine desire to advance the sport. As dedicated climbers, we recognize the pivotal role chalk plays in performance. But our work doesn’t stop at improving grip or managing moisture—we’re investigating the fundamental science behind chalk.

By exploring what makes chalk truly effective, we aim to optimize its properties for both performance and environmental responsibility. Our ambition is to produce chalk that’s gentler on the planet without sacrificing quality. We invite you to join us on this path of innovation and discovery as we push the boundaries of what’s possible in climbing.

Learn more about our Chalk Research Initiative

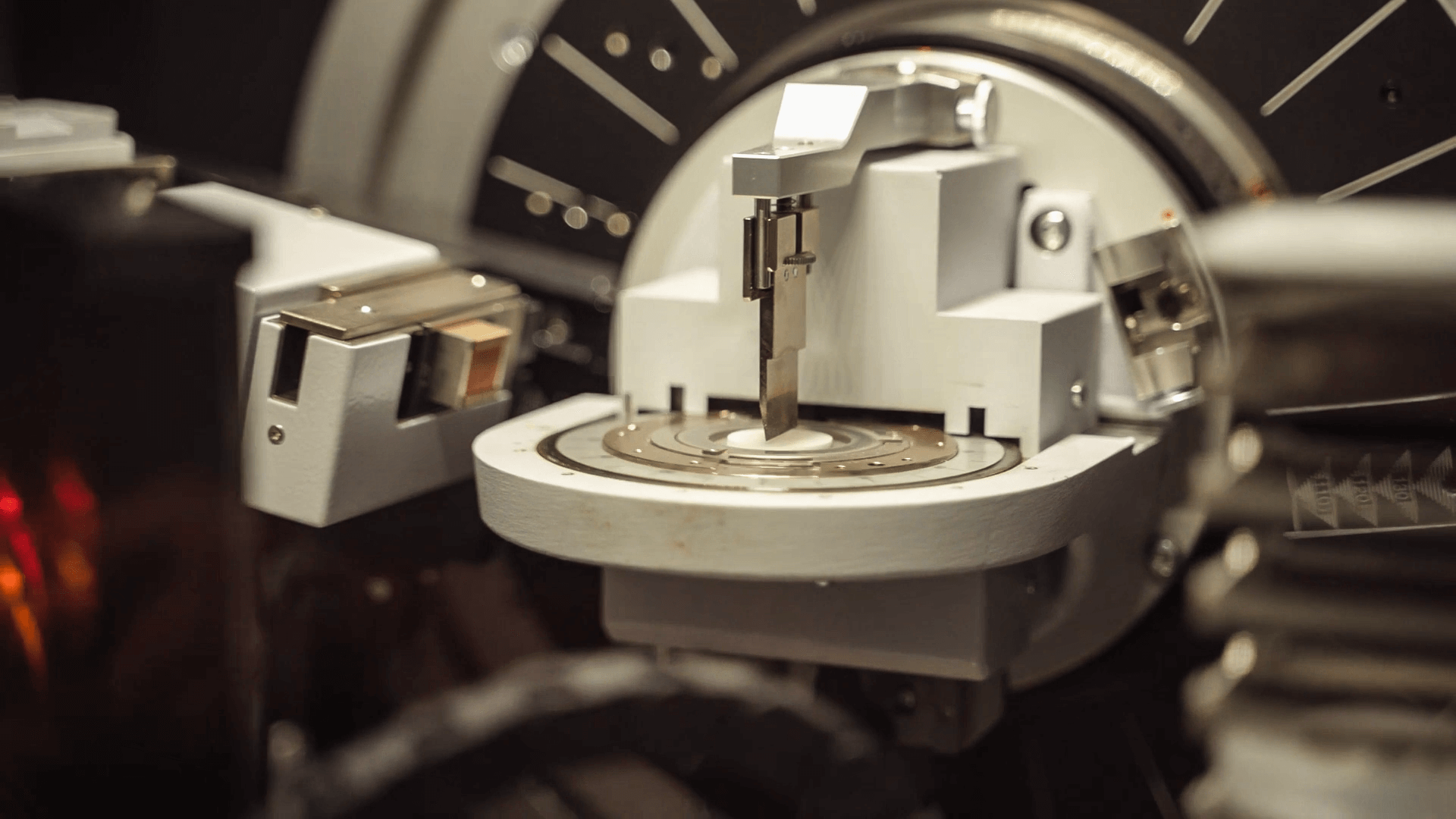

Accelerometer

Going back to 2004, bouldering pads were described as having the best dual-density foam on the market. There was no way to quantify these claims until Flashed introduced the test missile Drop Tester and we started putting a numerical value to impacts. This uses a headform missile for drop tests with a 3-axis accelerometer inside. Our focus was not on the padding, as some manufacturers focuses using load cells beneath the pads, but rather on the impacting missile itself.

Flashed has since upgraded our equipment and is able to perform head impact drops at nearly any gym height. This added information and tools are helpful to make informed choices.

Dynamic Fatigue

Durability is a key consideration when it comes to foam grade selection and, ultimately, helping decide which pad is best for you.

To understand the specifics of each foam type we needed to evaluate how the foam response changes over time with respect to both density and compression. The Dynamic Fatigue Tester (DFT), was developed to explore this relationship. An internal 3-axis accelerometer measures the g-force and by doing this with various foam densities and compressions we can better understand foam durability.

MOFO

The Multiple Overhead Fall Operator (MOFO) looks at testing a complete padding system, not just individual foam layers like the DFT. The MOFO uses single-axis CNC controls to perform of multiple drops at heights up to 18ft or larger.